GFRC or GRC stands for Glass Fiber Reinforced Concrete.

Fiberglass is a material used in the construction of boats or other similar products.

It is actually glass-plastic fibers reinforced with glass fibers in a polymer matrix. If we use Portland cement and sand instead of polymer, the obtained material is glass fiber reinforced concrete (GFRC or GRC).

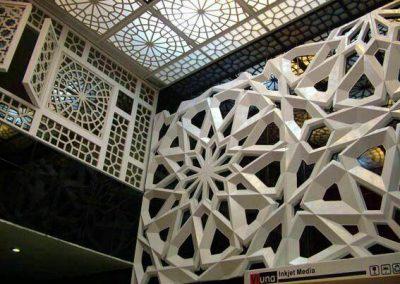

GFRC is kind of precast concrete it’s an amazing tool in the hands of world-class architects.

GFRC has been used for the last 30 years to produce many concrete products, especially thin cover panels. GFRC panel is also used to make decorative items such as domes, statues, workshops and fountains.

If you are not familiar with glass fiber reinforced concrete (GFRC), you should know that GFRC is specialized form composite concrete. GFRC was first produced in Russia in 1940s, and it was from 1970s that it was widely used for building facades in its current form.

this is a cement-based composite material that reinforced with alkali-resistant glass fibers. Fibers serve a similar purpose to reinforcing steel in reinforced concrete and also increase flexural, tensile, and impact strength. As a result, GFRC can be used to produce light and strong architectural concrete products such as building panels.

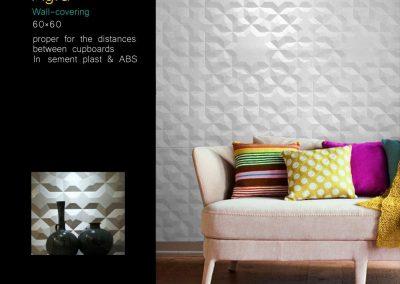

Also, due to its unique properties and tensile strength, it can be used to create decorative concrete products such as wall panels, fireplace surrounds, vanity tops and concrete tables. Most concrete countertop professionals use GFRC as their technique of choice due to its versatility, strength, and lighter weight. One of the best ways to truly understand the benefits of GFRC is to look deeper into this unique composition.

If you are not familiar with glass fiber reinforced concrete (GFRC), you should know that GFRC is specialized form composite concrete. GFRC was first produced in Russia in 1940s, and it was from 1970s that it was widely used for building facades in its current form.

this is a cement-based composite material that reinforced with alkali-resistant glass fibers. Fibers serve a similar purpose to reinforcing steel in reinforced concrete and also increase flexural, tensile, and impact strength. As a result, GFRC can be used to produce light and strong architectural concrete products such as building panels.

Also, due to its unique properties and tensile strength, it can be used to create decorative concrete products such as wall panels, fireplace surrounds, vanity tops and concrete tables. Most concrete countertop professionals use GFRC as their technique of choice due to its versatility, strength, and lighter weight. One of the best ways to truly understand the benefits of GFRC is to look deeper into this unique composition.

Advantages of using GFRC

lightness

Diversity in choosing different shapes and colors

No designer restrictions in choosing the shape

The possibility of execution on all levels (horizontal, vertical, under the ceiling)

High quality of finished surfaces (due to prefabricated production)

Durability against atmospheric factors

The possibility of using decorative designs

elegance

Maximum installation safety in the facade of high-rise buildings

Ease and speed of installation

Two-way view (aside from the impact on the urban visual landscape, it is also effective on the residents)

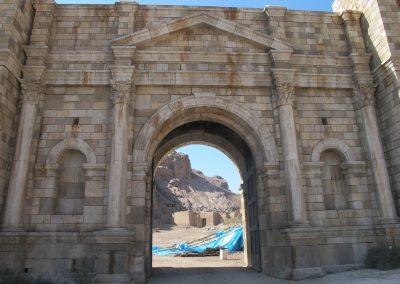

These days, with the tremendous progress in structural design and mazing architectures, materials and traditional implementation methods, not only are they not responsive to these innovations, but they are also not justified in terms of safety and economy. Therefore, since the 1960s, the Canadian Prefabricated Concrete Association has adopted a new method for building facade parts, which is use of glass fibers in concrete instead of steel in prefabricated facade parts.

Since bending and tensile strength of GFRC is higher than conventional concrete and precast concrete , GFRC products are widely used in the construction industry today. Against environmental conditions such as wind, rain, sunlight, even earthquakes, as well as the ability of GFRC to create any texture, shape and design that allows the building to blend better with the surrounding environment, has caused more advantages. compared to similar materials.

Hanza GFRC products are divid into two product categories

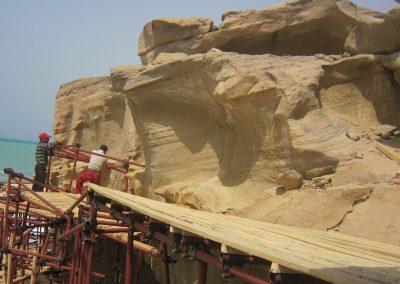

Volumetric GFRC parts

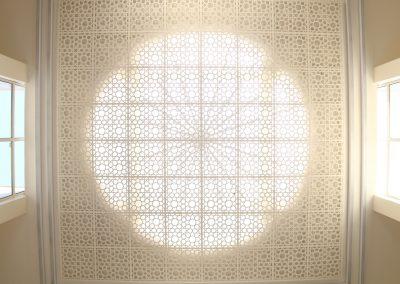

Internal and external GFRC facades

Gam-e abi company with its scientific, research and executive background in designing and manufacturing new construction products moved towards the design and production of various GRC/GFRC molds and parts and with its special capability in making 360-degree, double-sided molds, it tried to concern Help design engineers in the construction industry to implement their unique creations.

Sunscreen panels project of JFRC Central Bank by Henza

By now, you must have witnessed the progress made in the construction of structures, and also the designs of the huge giants and the shape of their internal and external facades have delighted you as well.

From the past until now, the materials used in construction have undergone changes and transformations, and some of these materials, which have been used even in the distant past, have been updated and changed today with modern and industrial methods. They have been used and they are used in more diverse ways in construction.

GFRCs are used in the facade of the building and this material has so much strength and resistance that they last against environmental conditions such as wind, rain, sunlight and even earthquakes and do not get destroyed.

Also, by purchasing GRFC panels, you can order them both in a smooth surface and in various textures.

Advantages of GFRC panels (GFRC | GRC)

Among the advantages that can be considered for these panels are as follows:

high resistance

No design restrictions in the choice of forms

The possibility of execution on all horizontal, vertical, under the ceiling

Diversity in choosing different shapes and colors of facade

Durability against environmental factors

The possibility of using decorative designs

Lightness and elegance

High quality of finished surfaces

Maximum installation safety in the facade of high-rise buildings

Ability to make light panels

Structural properties of GFRC panel (GFRC | GRC)

If you are interested in what is the reason for all the resistance and stability of GFRC panels, it is better to know that these panels get their strength from a high dose of AR glass fibers and a high dose of acrylic polymer.

This is because these panels also have high compressive strength, which is due to the low water-cement ratio and high cement content, which causes them to have very high bending and tensile strength, which is several miles higher than ordinary concrete. May special superiority be given to these panels.

The same thing can be the reason that it easily tolerates the amount of tensile loads and the large amount of polymer can cause high flexibility and no cracking in the long term.

The most important applications of GFRC parts

Among the most important applications of GRC panels, we can mention the following:

making columns, domes, decorative ceilings and walls, statues, fences, decorative pieces for interior and exterior decoration of buildings, as well In the construction of marine structures such as docks and floating bridges, channels for cable laying, water channels, storage tanks.

بدون دیدگاه