Using of concrete panels is one of the new construction methods that is recommended for buildings that require thermal, acoustic and high resistance insulation. Concrete panels have become popular in the construction industry due to their special features and better performance than conventional methods. Concrete panel consists of two metal sheets with an average of concrete which are continuously connected. These panels have a very high efficiency in thermal and sound insulation due to two metal layers on the outside and inside, as well as thermal, acoustic and sealing materials inside the panel.

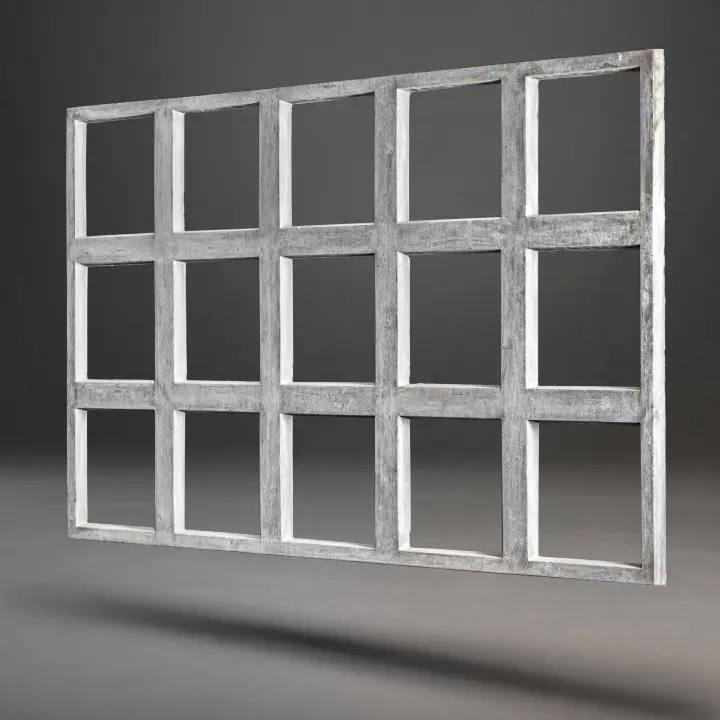

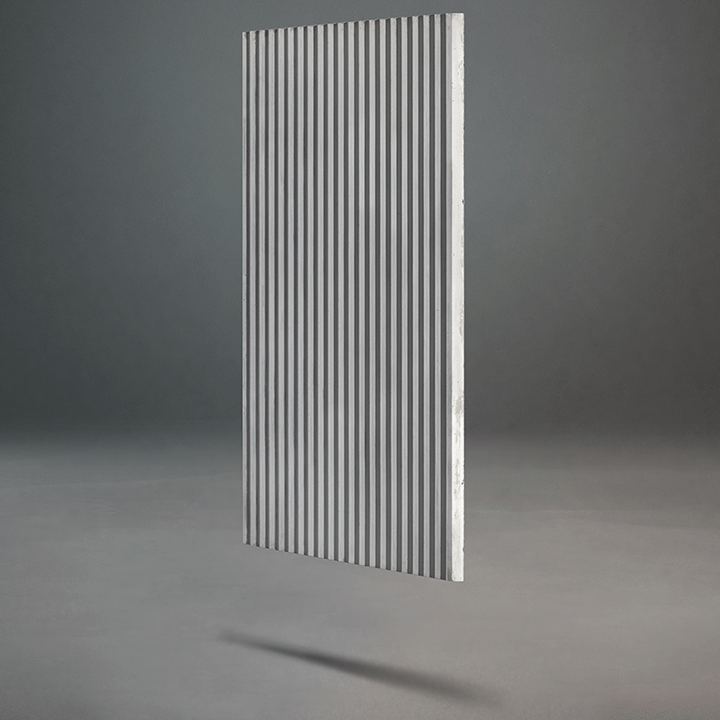

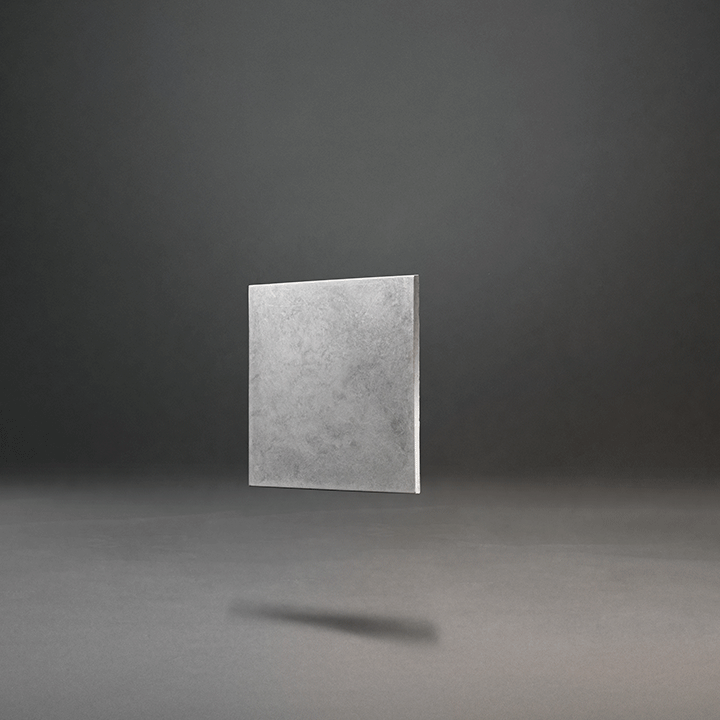

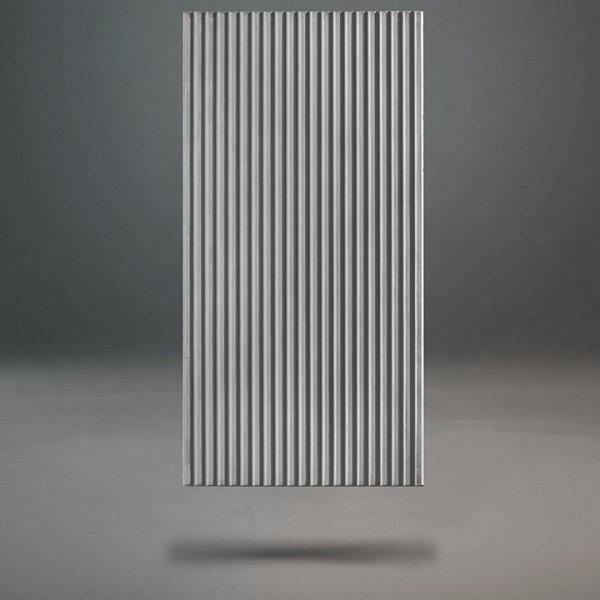

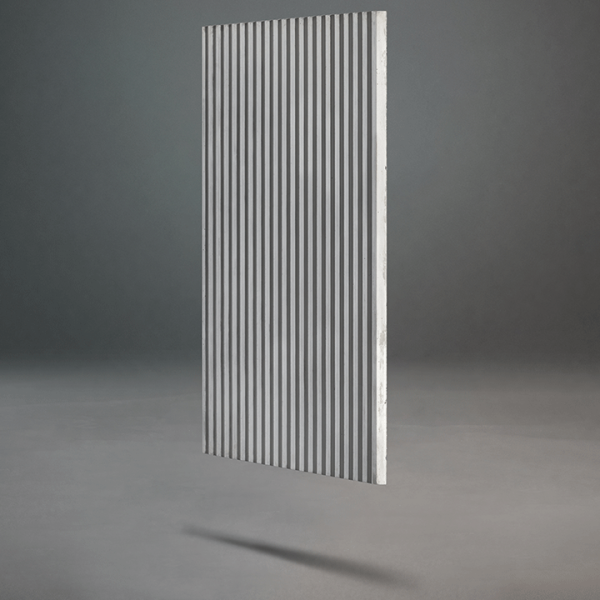

Concrete Panel Products

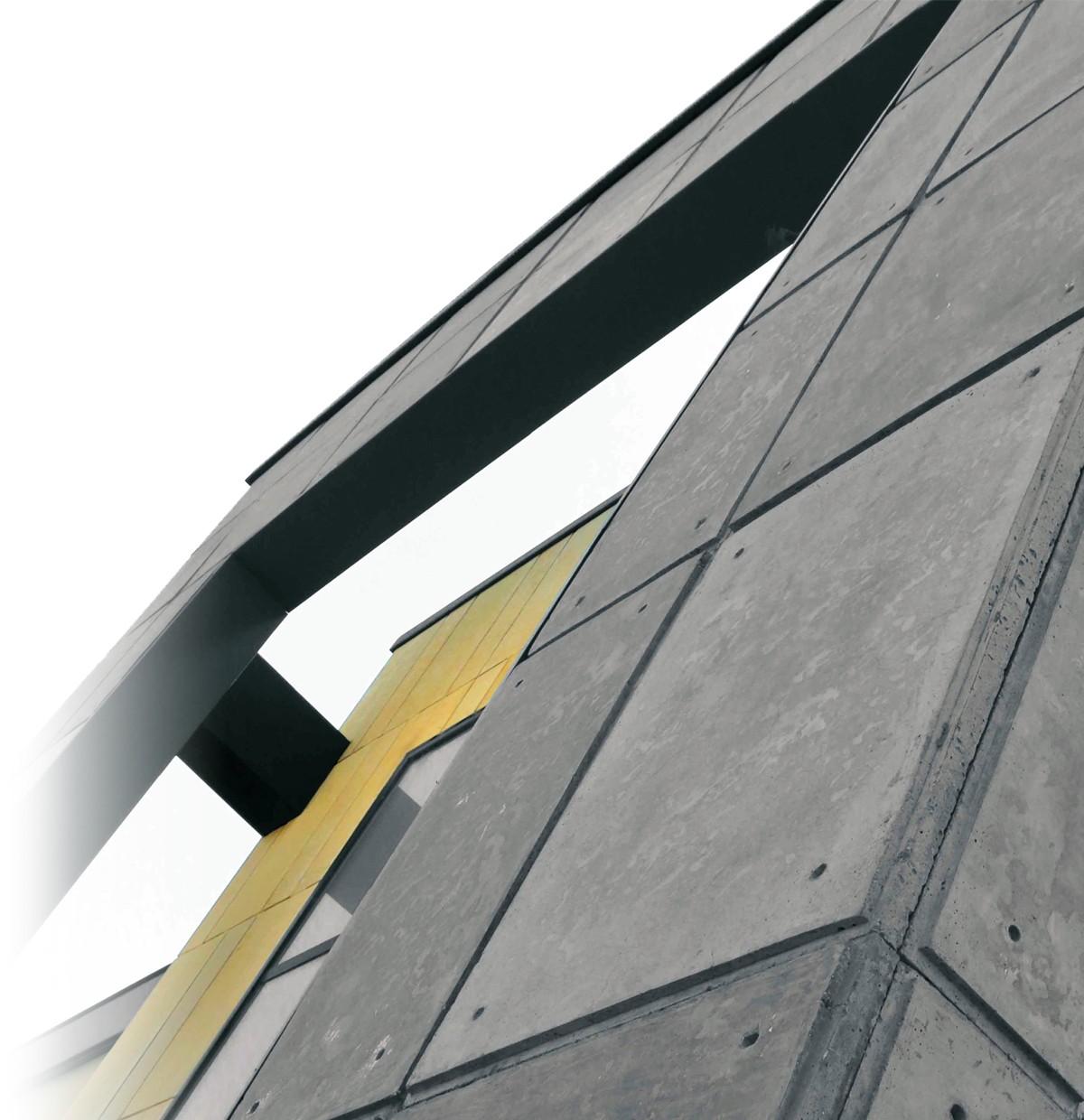

Concrete Panel work samples

Concrete panel buying

To buy a concrete panel, you can do the following :

- Research: Collect complete information about the concrete panel and its specifications. This research includes dimensions, strength, thermal and sound insulation characteristics, different uses and prices . By comparing different options , you can make the right decision.

- Determining your needs: Before buying, determine your needs. This includes the amount and dimensions of the panels you need, their thickness and insulation strength, as well as other features that are important to your project.

- Advice: contact experts and reputable sellers in this field. They can guide you in choosing the right concrete panel as well as how to use and install it.

- Compare prices: Compare prices at several stores and suppliers before buying. But note that the cheapest option is not always the best option, quality and performance should also be considered.

- Purchase: After doing your research and making a decision, proceed to purchase the precast concrete panel from the seller you have chosen. It is recommended to always cooperate with reliable and experienced suppliers in order to have the necessary quality and standards. Also, don't forget to check the rules and regulations related to the purchase and use of concrete panels in your area.

The price of the concrete panels

Precast concrete elements are a great way to simplify your construction project, r the time reducing and reduce the overall cost. Another advantage of using precast concrete instead of cast concrete is that precast product forms can be custom made to any shape. For example, it may be architectural, decorative, structural, ornamental, large or small. The construction of precast concrete panels is more complicated than precast blocks. Concrete panels usually use more concrete because they are often used as flooring and other load-bearing elements. There is also a tendency to further strengthen the steel, which requires surface treatment.

The price of concrete panels is affected by several factors. Some of the influencing factors are:

- Panel dimensions and thickness: The dimensions and thickness of concrete panels have a direct effect on their price. Larger and thicker panels may cost more.

- Type and quality of concrete: The type and quality of concrete used in panel production also affects its price. High quality concrete may cost more.

- Strength and technical characteristics: strength and technical characteristics such as compressive strength, thermal and sound insulation and other characteristics of prefabricated concrete panels also affect it’s price. Panels with multiple and improved features may have a higher price.

- Order size: The size of your order can also affect the price. Larger orders may result in discounts and better prices, while smaller orders may be more expensive.

- Geographical location: The geographical location of the project can also be influential. The cost of transporting concrete panels to the project site also affects the final price.

- Market Conditions: Market conditions usually have a direct impact on concrete panel prices. Factors such as supply and demand, price of raw materials, production cost and inflation rate can affect the price.

Generally , the price of concrete panels depends on several factors, and it is better to consult with different suppliers and make a detailed comparison before buying in order to choose the best option according to your needs and budget.

Implementation and installation of concrete panels

Precast concrete panel is a type of building structure that is produced in a factory before being built and installed on site. These panels are usually made of light concrete and are produced as ready-made parts with standard dimensions. After their production, they are moved to the construction site and installed using different methods such as welding, bolting and gluing. Concrete panels are used in external and internal walls. Using a concrete panel system has many potential advantages over cast-in-place. The production of concrete panels is usually done at ground level, which helps to control safety aspects during the casting process. There is also more control over the quality of materials and workmanship in a prefab factory compared to on-site construction. The efficiency, durability, ease, affordability and sustainable features of these products have created a revolutionary change in the time spent of building multistorey structures.

Concrete panels are very versatile in the industry and the way they are used. These panels are used in many projects due to their unique characteristics. Some of the important applications of concrete panels are: Residential buildings: Concrete panels are used as external and internal walls in residential buildings. These panels can be placed horizontally or vertically. Commercial and industrial buildings: Concrete panels are also used in industrial and commercial projects such as factories, warehouses, sports halls and commercial centers. These panels are suitable for this type of buildings due to the speed and high quality of construction. Construction projects: Concrete panels are used in construction projects such as bridges, tunnels, cable cars and transportation structures. These panels are suitable for these types of structures due to their high resistance, long life and ability to bear heavy loads. Interior and exterior: Concrete panels are also used for the interior and exterior of buildings. These panels can be used as separators, covers, decorative walls and facade coverings. Modular and removable systems: concrete panels are used in the construction of modular and removable systems such as temporary buildings, passenger carriers, containers and removable residential units. These are just some of the applications of concrete panels, and in fact, these panels can be used in many fields and construction projects.

Variety in precast concrete panels

There are various designs of precast concrete for architectural usage in terms of size, performance and cost. Prefabricated panels are also used to cover all or part of the facade or independent walls concrete panels are used for landscape and paving , sound insulation, security walls, and some can have prefabricated concrete structural elements. Concrete panels are used for rainwater drainage, water and sewage pipes and tunnels. It’s essential that each part of the structure is designed and tested So that withstand the tensile and compressive loads that the panel endures during it’s lifetime. Also, the designers of precast panels must follow the practical guidelines and standards of construction and keep up the safety of the overall structure and building design. if any change in the design of the building panels is required these changes must be done before installation. There must be a process to manage these changes so that the panel design parameters are not exceeded and the structure design is not compromised.

Advantages of precast concrete panels

- Time Saving in construction: construction with prefabricated materials saves time and reduces the risk of project time.

- Use of prestressed concrete: structural materials with high strength and bearing capacity can be obtained by using prestressed precast , which results in clearer openings , smaller parts of structural components & etc.

- Quality Assurance: It should be monitored for important parts such as curing, temperature, mix design, formwork, etc. that affect the quality of the concrete panel and thus the quality of the building. Concrete panel is one of the fastest building constructions and reduces the negative consequences of on-site projects. Thus improved quality construction is achieved.

- Durability: Structures made of prefabricated materials last longer and require less maintenance. High-density precast concretes are resistant to acid attack, impact and corrosion , reducing scratches surface and resisting the accumulation of dust or mold that can cause health problems.

- Cost-Effective: This efficient construction process saves time, improves productivity, quality and safety, thereby reducing costs.

- Safe construction : Precast concrete panel construction does not require on-site storage of raw materials. This eliminates the need for traditional work and support, as well as the waste of manpower and other factors, thereby creating a safe work environment.

Disadvantages of precast concrete panels

- High initial investment: Heavy and complex equipment is needed to install the concrete panel, which requires a lot of initial investment . For return on investment, a significant number of prefabricated construction projects must be provided.

- Transportation issue: The building site may be far from the precast concrete facility. In such a situation, trailers are used to transport prefabricated panels to the workplace. In many situations, the lower cost of concrete panels is offset by higher shipping costs.

- Transportation problems: Transportation of prefabricated concrete panels requires extreme caution. Precast members are often heavy and bulky, making them difficult to work with without causing damage. Precast elements often work with portable or tower cranes.

- Modification: It is difficult to change the design of a precast concrete structure such as a panel. For example, removing a structural wall for renovation, will affect the overall stability of the structure.

- Sensitive connection work: One of the most important aspects of maintaining excellent structural behavior is the assembly of precast concrete components. Joints between multiple structural parts, whether simple, semi-rigid or rigid, must be monitored and completed to ensure joint integrity. Faulty panel connections can also lead to water leaks and loss of sound insulation.

Possible risks while installing concrete panels

Many workers have been seriously injured or killed during the installation and final removal of the concrete panel. It is important to pay attention to the fact that the people involved in the installation of prefabricated panels must be fully aware of the methods of each stage of installation and removal in a planned manner. It is important that the roles and responsibilities of each worker are clear and communicated to everyone. Under no circumstances should anyone do things like remove things without proper training and permission. Only qualified, suitable, trained and supervised workers can participate in the installation of prefabricated panels.

The collapse of any concrete panel, even a small one, can have catastrophic consequences for workers or the general public. The risk of panel collapse exists at all stages of construction, not only during panel installation, but the risk of collapse must be managed until the concrete panel is effectively attached to the permanent structure of the building. Installing concrete panels, using a mobile workshop around the panels and changing or removing temporary bracing is always risky and requires the preparation and follow-up of a safe work procedure (SWMS).

بدون دیدگاه