Exposed concrete is typically referred to as concrete with a smooth and polished visible surface. This means that no additional covering is applied to the concrete surface. Therefore, in such types of concrete, the visual quality and surface finish are of high importance. This is especially significant in buildings and architectural structures, where it plays a prominent role.

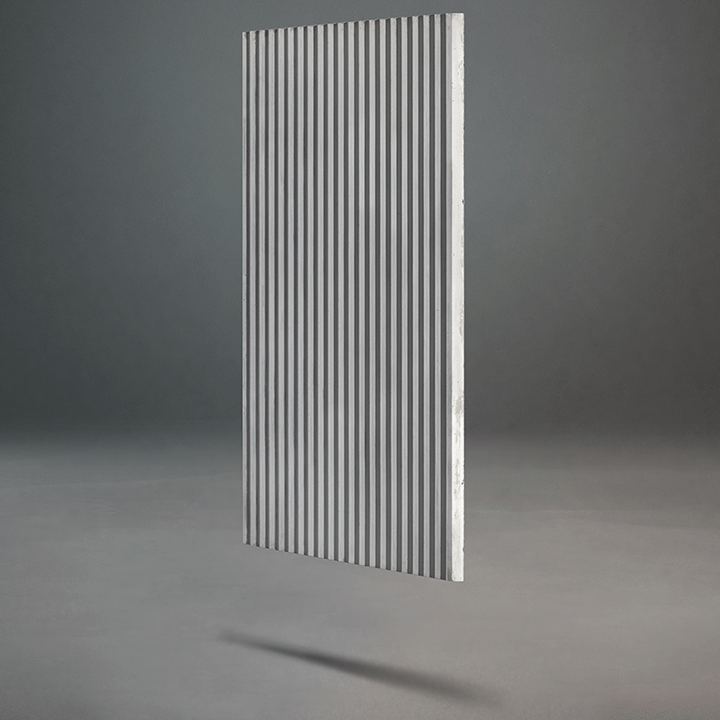

Pre-cast Exposed Concrete allows for the production of concrete components while preserving the mentioned characteristics. This means that reinforced concrete elements with the desired design and size can be manufactured in a factory environment.

Advantages of choosing precast exposed concrete, such as HENZA, over others include:

1.Implementation of design and patterns according to preferences.

2.Ability to be executed in dimensions and sizes specific to the project.

3.High construction speed.

4.Long lifespan.

5.Installation capability with adhesive mortars or dry connections.

6.Ability to be constructed in all seasons.

Characteristics of precast exposed concrete:

Production under controlled conditions in an industrial environment, adhering to relevant standards such as mix design, processing, elimination of concrete degradation factors, and more

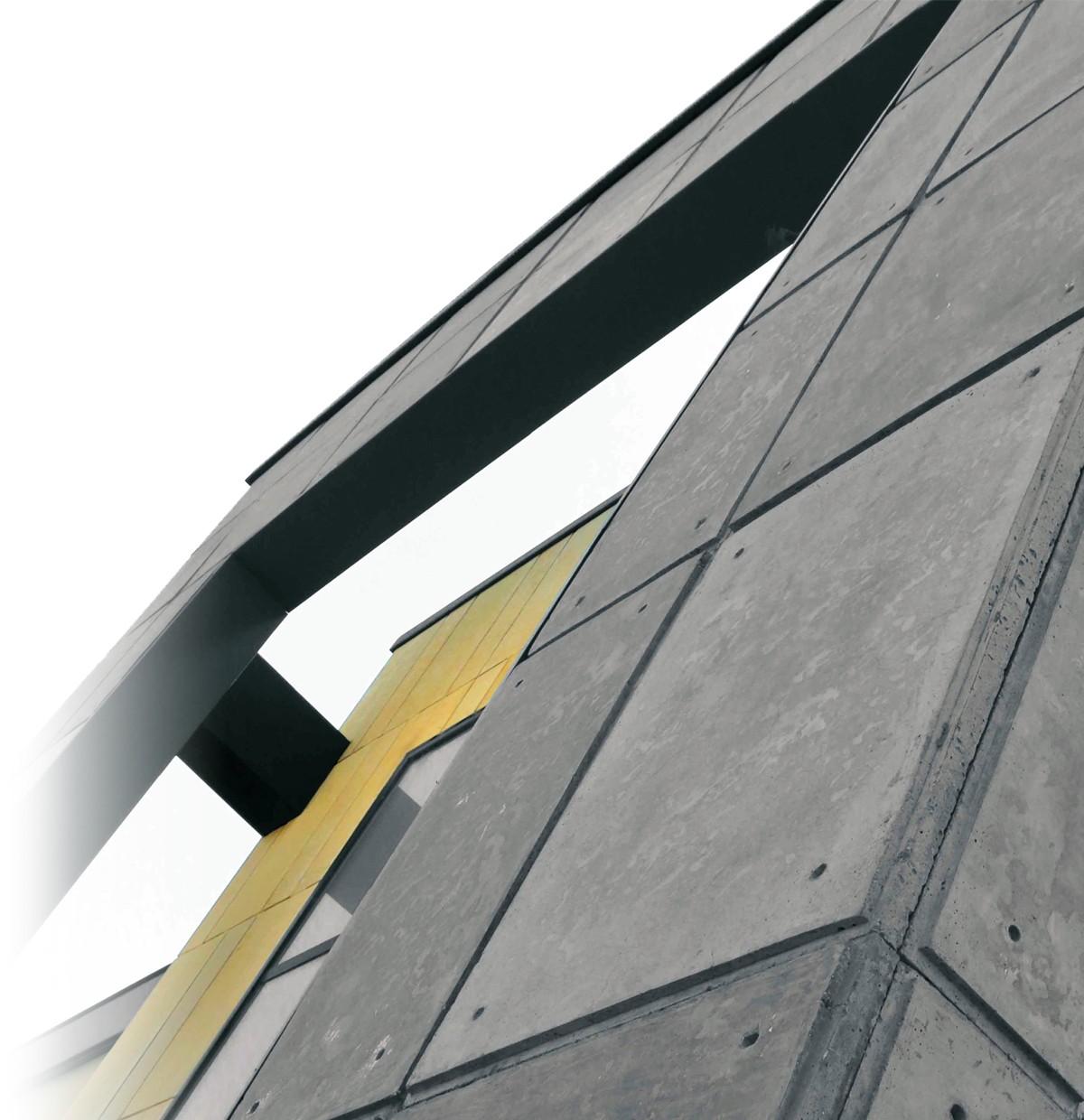

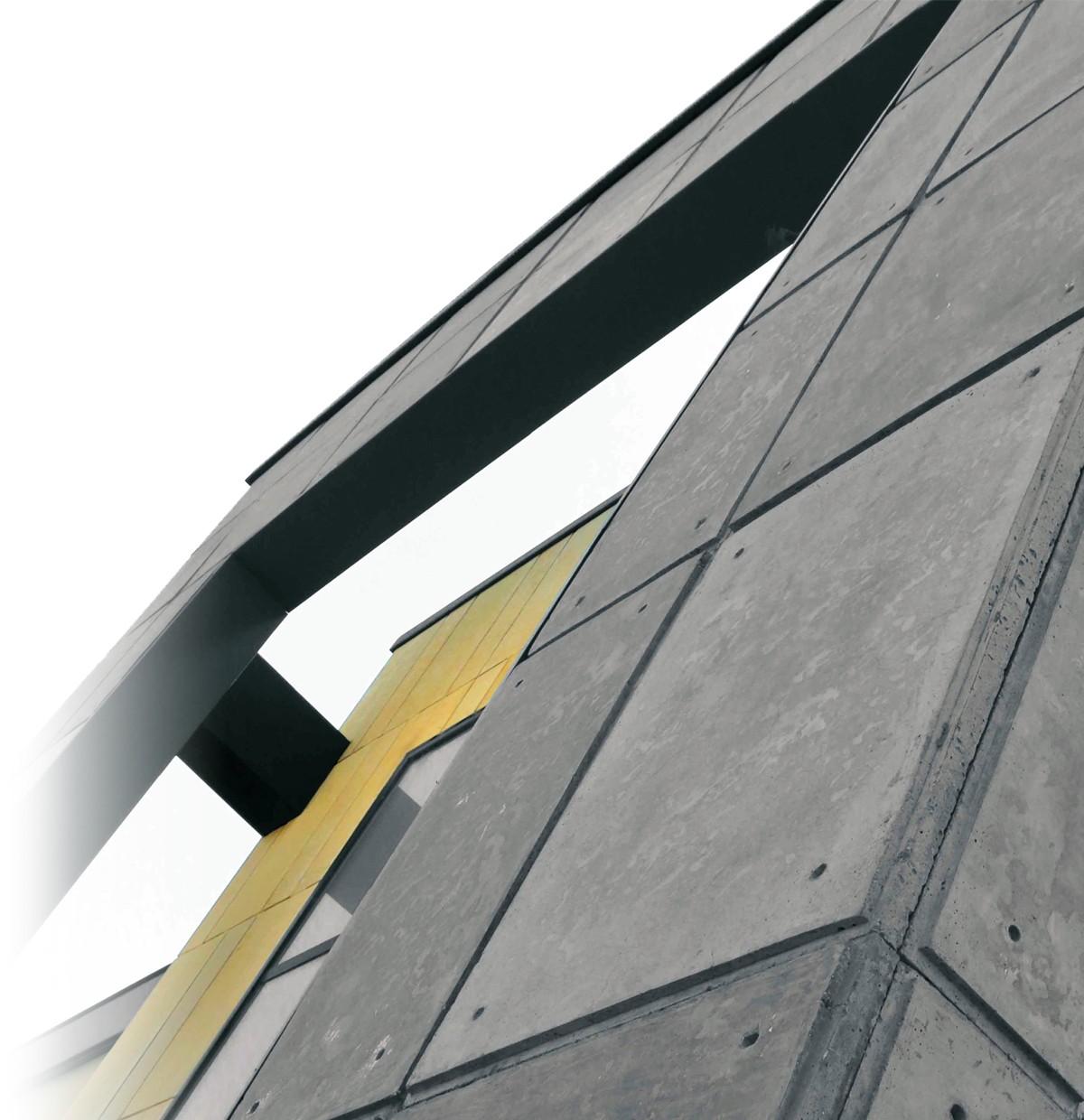

Exposed Concrete work samples

What is exposed concrete?

Exposed aggregate concrete is one of the most well-known building materials to date. It is obtained by adding different additives in the concrete mix design and can be used in landscaping and building facades. One of the most commonly used types of exposed aggregate concrete is facade exposed concrete, which is used by installing precast concrete panels as the exterior facade of a building. It can be installed using either dry or wet methods. The material called exposed concrete or facade concrete in English. This material, in fact, refers to precast concrete panels that have a wide range of applications due to advancements in technology. As mentioned in the previous paragraph, it can be used in modern architecture, external cladding, interior decoration, floor covering, outdoor furniture construction, and staircase construction.

Exposed Concrete history

For the first time, the use of exposed concrete was seen in the construction of Corbusier's commercial building, which is located in Harvard University, and this project was able to attract the attention of engineers and building designers. This caused the use of concrete facades to gradually increase. So that between the years 1970 and 1990, the use of exposed concrete expanded rapidly. This issue caused the prosperity of technologies and processes related to concreting and concrete production.

Expose concrete and its variation

Greetings dear companions. In this article, we will talk about the purchase of exposed concrete and its price, as well as what is exposed concrete and what are it’s variations? We will share information with you. Exposed concrete is one of those building materials that is very widely used in the field of construction and has been used by all people who have been engaged in construction since the very distant past. Among the features that have made all builders to purchase exposed concrete in all eras is that this building material is very practical and has a long lifespan, and its price is very affordable and appropriate among other building materials. In addition to all the above, due to the progress that has been made every day in the field of technology and construction, this construction material has also increased its productivity and caused many architects, engineers and contractors to continue to use this material. continue to use the material and use it in external architecture and construction of facades as well as internal architecture. But with all these interpretations, let's go to what is this material and what exactly is it for builders? Stay with us. Concrete is one of the widely used and available building materials that have been used in construction for a long time.

Expose concrete property

This material has amazing characteristics that justify the purchase of exposed concrete and its continuous use. But it is generally used on external surfaces, and thus it is one of the last materials used for decoration and is not combined with other materials or used with new materials. Of course, keep in mind that for the final look, it can be combined with a material such as wood, which gives a very beautiful and special effect to your work. Keep in mind that these concrete panels can be designed and produced in standard & custom sizes. Some people think that, like in the old days, it is only possible to buy exposed concrete and place it in panels that have polished and smooth surfaces, while today the hands of the producers of this panel are very open and they can according to the customer's design. produce different designs of this material.

Among the different types of this material, we can mention things like: exposed pyramid concrete, exposed block concrete, exposed tri-angle concrete, exposed prism concrete, etc. None of the items that we have introduced before have a smooth surface and they are very suitable and beautiful for use on the exterior, and with their lighting, you can give a beautiful and unique decoration to the environment.

But it is a very important feature that makes builders more encouraged to buy exposed concrete are the following:

- High resistance in different weather conditions such as humidity and extreme cold to be economical

- Sound and thermal insulation

- Resistant to fire and fire

- Can be designed and produced in custom dimensions

- environment lover

- Long service life, because the raw materials of exposed concrete are the same raw materials of concrete The

- possibility of performing its executive operations in all seasons due to high resistance

- Production and implementation capability in various dimensions and sizes according to needs

- Increasing the execution speed and reducing the project time compared to the use of other materials

- Ability to install with mortar or dry joints

- Ability to be used with other materials and colorability of external surfaces of concrete.

Exposed concrete is implemented in two ways

Concrete has been used for many years in the construction of buildings and civil structures as a strengthening material. This product is used in various building parts such as walls, columns and roofs. But if concrete is used to cover the facade of a construction project, it is called exposed concrete or exposed concrete. Of course, the use of exposed concrete is not only limited to the exterior wall of the building, but it can be used in the interior of the building walls as well as the flooring of the building and the flooring of the exterior spaces of the building area. Of course, the use of exposed concrete can be considered wider than these cases. Today, in the dam building industry, concrete can be used to cover the dam walls. Also, in the construction of tunnels, bridges, underpasses and the like, we see that many designers and builders cover their surface with exposed concrete. Exposed concrete is very popular with those who are looking for uniform, minimal and modern spaces for the interior design of their building because of its integrated surface, special color and the cold feeling it induces. Of course, it should be noted that the function of the concrete facade cannot be limited for this purpose.

Precast exposed concrete

This category of exposed concrete is called concrete which according to the customer's request and based on its construction plan and the size and dimensions of the facade, as well as the design considered by the facade designer, in the factory of prefabricated exposed concrete panels in the design, shape And the desired color is produced. Then they move this product to the project site or the same building and install it in place with the appropriate method. Earlier, we talked about the various methods of installing exposed concrete panels and said that the installation of this product is usually done in different ways, which include: installation by sticking the panel to the wall with a special adhesive. Installation by using cement mortar as well as mechanical installation by placing the panels in special metal rails and securing them with bolts and nuts designed for this purpose.

Implementation of exposed concrete at the project site

In this method, instead of designing the exposed concrete panels in the factory, the surface on which the exposed concrete is to be installed is molded in the desired project site, and concrete is poured into the molds, and then they are allowed to The concrete in the molds is dried, then the mold is removed and the molding is done in another place and the concrete is poured again. method, the molding starts from the lowest surface of the facade and we gradually move towards the upper levels until the entire surface of the facade is covered with exposed concrete. Usually, the on-site concreting method is used for very large projects that have an almost uniform and integrated design and do not need to prepare prefabricated panels. Also, the execution speed of this method is higher for installing exposed concrete. Factories active in the field of prefabricated exposed concrete panels, in addition to being able to design and produce the desired panel based on the customer's request and taste, they usually produce some widely used designs of this product in advance as exposed concrete panels. that customers can choose their desired exposed concrete factory for their building from among the production plans.

Types of concrete facade

In this part , it’s necessary to talk about the different types of this concrete product. Concrete facades or exposed concrete are made and designed in two general types, prefabricated and usable on site, and any manufacturer can order any model according to their needs. But we have to give explanations about these two models for better understanding.

Exposed concrete applicable at the project site

By buying exposed concrete, which can be applied at the project site, in fact, you can have these concretes in very large sizes, and generally, this type of concrete is used in the implementation of large work projects, and as the name suggests, Construction to execution and molding on the site of the construction project is capable of foundation. Reasons for using exposed concrete for external facades One of the reasons that can be mentioned in buying exposed concrete for use in external facades is that these concretes have very high strength and resistance and are very compatible in weather conditions such as humidity and heat. Reasons for using exposed concrete for facades One of the reasons that can be mentioned in buying exposed concrete for use in facades is that these concretes have very high strength and resistance and are very compatible in weather conditions such as humidity and heat.

Among the uses of exposed concrete, the following titles can be considered:

Exterior view with the exterior of all kinds of buildings

Construction of swimming pools and ponds

Construction of stairs

Flooring of the building

The interior walls of the house and all kinds of interior decoration

Urban areas such as parks and city streets

Urban walls and facades

We hope that by purchasing exposed concrete, you will be able to implement the best and most beautiful designs in the interior decoration, and you will be able to have the most stylish designs in the exterior of the building as well. If this article was useful for you, send it to your builder friends or your architect and engineer.

Exposed prefabricated concrete:

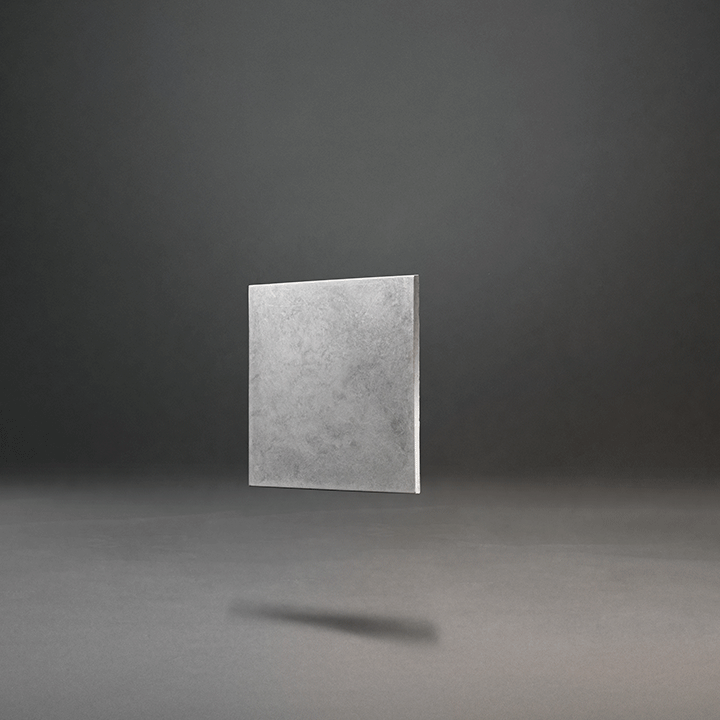

Precast concretes are called exposure concretes, which are produced and delivered to the customer in standard sizes and sizes according to their usual routine. Although some customers may order and buy exposed concrete, these dimensions may be changed and customized. Henza company has the possibility of making prefabricated exposed concrete according to the tastes and ideas of designers and architects. This means that it is possible to make reinforced concrete parts with the desired design and size in the factory environment. Prefabricated exposed concrete panels are used for interior and exterior facades of the building. These panels can be produced in different dimensions and used in all seasons. Due to the non-use of other materials on this type of concrete, the beauty and quality of its surface is extremely important, so that the presence of dents and protrusions on the concrete surface reduces its appearance. The panels used for the exterior of the building must have the necessary resistance against changing weather conditions and prevent water from entering the lower layers of the structure. But in the interior view, beauty is more important because the work surface must be smooth and scratch-free in order to be able to paint and perform work related to interior decoration.

Uses of exposed concrete:

The use of exposed concrete panels is possible in any situation. Below we are going to mention the cases in which the best option is to choose exposed concrete panels.

- When we are looking for a material with high strength for villa landscaping and parking, or a material that can withstand traffic loads, such as factory premises, where heavy machinery passes.

- If you are looking for a special design with different shapes or with an arch in the facade of the building and it is not possible to make these designs with natural stone, be sure to use this panel by dry installation method.

- If you are looking for a modern and beautiful design, you can achieve it by using a combination of artificial grass and exposed concrete panels.

- If you are looking for a long life, especially in cold regions, one of the most appropriate options is to use a concrete panel.

Use of exposed concrete in sports spaces: Using a concrete panel in a sports space can have two important features:

- Due to the possibility of damage to the walls in sports places, exposed concrete is the best option with its good resistance.

- By creating a combination of exciting colors, it brings a modern and beautiful atmosphere.

Advantages of exposed concrete with stone ratio:

There are several major features that make exposed concrete superior to stone. Exposed concrete has the ability to adapt to other facades due to the inherent nature of concrete. It can also establish harmony between exposed concrete and other materials such as wood and brick, which cannot be seen in stone. Exposed concrete installation time is faster than stone. First, because the panel sizes are ready, and second, due to the presence of a ready scope in exposed concrete panels, there is no need to scope like a stone. Weather conditions are also influential, and in case of weather changes, stones such as travertine, which have porosity, will crack and break due to the absorption of moisture. If such problems do not arise for exposed concrete.

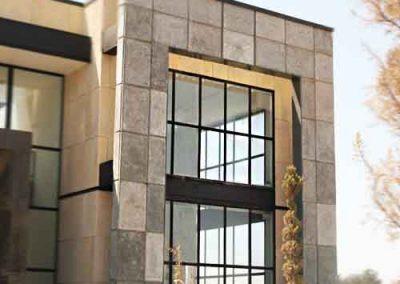

Tips related to the implementation of exposed concrete:

As mentioned above, exposed concrete has a very high flexibility and can be used in various applications, even in industrial complexes. In this project, the combination of concrete, stone and glass panels has been used, which, in addition to high resistance and strength against cold weather, provides a pleasant and modern space for the employees of the complex in terms of architecture. When using this material, the designer must be careful to use this material in the right place, because the incorrect use of this type of concrete will create an inappropriate surface like an untreated surface, and at the stage of Second, the coldness of the concrete should not make the atmosphere rough and cold. To prevent this,concrete should be used in combination with other hot materials.

Method of dry installation of exposed concrete:

In this method, which is a mechanical method, we place corners on the wall where we are going to install exposed concrete panels and parts, and we make a metal foundation on the surface of the corresponding wall. Then, using the tool that we install on the back of the exposed concrete panel, we can screw the exposed concrete to the corresponding wall and the corners and the metal foundation that we have prepared. In this method, which is completely mechanical and does not use grout or any glue, there is no need to wait for the mortar to dry, and this method of installing the exposed concrete panel is completely clean and removes the dirt that may be caused by grout or glue. does not come with But we have to make sure that the connection and screws are tight.

Advantages of exposed concrete dry installation:

Very high strength and resistance

High execution speed no large increase in the weight of the structure due to facade construction, ease of repair and reconstruction of the facade of the building.

Exposed concrete grout installation method:

To install with grout or mortar, we must first connect the panels to the wall so that we can pour grout in the space behind it to strengthen it. There are two ways to do this. Create gaps behind the exposed concrete panel so that we can connect them to the wall through these gaps.

- We put wires behind them and connect these wires to scopes on the wall and fasten them.

- Among the advantages of this method, it can be mentioned that it is cheap and faster to install than the dry method.

But if the project where we intend to use concrete to cover the surface with its facade has a wide surface, instead of using prefabricated panels, the necessary moldings are done on site and concrete is poured, which This arrangement of exposed concrete is implemented for these construction projects.

Of course, it should be noted that in this method, after the exposed concrete has dried in place, we remove the molds from the surface. But in this article, we are going to address the issue of what materials are used to produce facade concrete and whether there is a difference between the raw materials used to produce facade concrete and raw concrete or not. That is, is the difference between exposed concrete and ordinary concrete only related to the place of their use or do they also have differences in the construction stages.

The answer is that the main ingredients of exposed concrete are the same ingredients of ordinary concrete, which include cement, water, and aggregates, which are fine grains of sand that are mixed together in a specific ratio. But in addition to the proportion of raw materials that can be different between ordinary concrete and exposed concrete, some additives are used in the composition of exposed concrete, which are usually not added in the composition of ordinary concrete. These additives include:

Exposed concrete filler materials:

These fillers increase the density of particles in concrete. In this way, the density of exposed concrete increases compared to normal concrete, and this causes greater adhesion between exposed concrete particles. The reason for this is that because exposed concrete is used in the facade of buildings or structures, it must be able to resist the penetration of foreign materials such as moisture or other particles. Because if water, moisture or other foreign materials penetrate exposed concrete, its composition can easily fall apart and fail.

Super-lubricating materials for exposed concrete:

The function of the super-lubricant material is to give a smooth and polished surface to the exposed concrete, which makes it look special and the view that is covered with exposed concrete is beautiful and attractive. Especially if exposed concrete is used in the interior, it is necessary to pay special attention to the beauty of its surface. Because concrete normally has a rough surface with cracks. Therefore, the addition of fillers and super-lubricants allows exposed concrete to maintain its resistance and beauty. For this reason, you can refer to Hanza's exposed concrete page and see samples of Hanza's production panels. You can also refer to Hanza experts and specialists for your order.

How is exposed concrete prepared?

Exposed concrete, which is referred to as concrete that is exposed to the surface of the work and is actually the final surface of the work and nothing is covered on it, has recently become popular because of the special color and effect it can give to the exterior or interior of buildings. Attention has been paid. Especially since it is a combination of a unified and modern view of the basement.

But one of the issues that is very important is the method of making and producing exposed concrete, the more this step is done with more accuracy and compliance with the necessary standards and points, the produced exposed concrete has a higher quality, both in terms of appearance and in terms of Quality and stability can be more reliable for building builders. The method of making and producing exposed concrete is called exposed concrete mixing plan.

In order to get acquainted with the production method of exposed concrete, the first step is to see what materials and composition exposed concrete is made of. As we have mentioned before in the series of articles by Hanza experts, exposed concrete is a combination of various materials that include cement, sand aggregates, water, additives and lubricants.

As you can see, the composite materials of concrete look are the same materials that are used in the construction of concrete. But since exposed concrete is used in the exterior of the building, it should have better features in terms of beauty, uniformity, durability and longevity. On the other hand, exposed concrete is exposed to wind, rain, sun and different weather conditions, which is why it is necessary to have sufficient resistance to different external conditions. And this makes the concrete mixing plan different from the normal concrete mixing plan.

In order for the facade concrete to have the required strength, after it is molded, the volume of concrete is vibrated with a vibrator, which causes the bubbles between the surface of the exposed concrete to come out and compaction. It will increase.

In addition, lubricants and fillers that are added to exposed concrete improve its strength, but you must be careful that the mixing time is limited and less than ten minutes, because if the time is longer, it will cause the sand grains to and the cement will slip and separate and the uniformity of the exposed concrete will be disturbed.

Sealing molds and using the right oil for exposed concrete molds are also important issues in the facade concrete mixing plan, which you can contact our experts in Hanza to learn more about. Also, you can see the final examples of projects in which facade concrete is used on the Beton Expose Hanza page.

بدون دیدگاه